The rapidly-increasing commercialization within the 3D printing area has already led to large development in particular verticals like ceramics and steel. A latest report instructed that the ceramic 3D printing market may attain 384 million USD by 2025. The steel market, which is taken into account one of many quickest rising within the AM sector, is predicted to surpass $18B by 2032 for comprehensible causes.

3D printing utilizing the above supplies permits the creation of complicated components with superior mechanical properties. NanoParticle Jetting™, the signature strategy of AM 3D printing chief XJet, is appropriate with each ceramics and metals, providing an automatic, secure, environmentally pleasant path towards scale manufacturing of high-quality, geometrically complicated components. We spoke with the corporate’s CMO, Man Zimmerman, to be taught extra concerning the know-how, its advantages, and XJet’s distinctive method.

3DN: Might you introduce your self and Xjet?

My title is Man Zimmerman. I joined Xjet just lately because the CMO as the corporate gears up for development. I’ve numerous expertise, although most related is my background in world enterprise. In the meantime, Xjet is a 3D printer producer that’s addressing probably the most difficult phase in additive manufacturing, metals and ceramics. Top quality, prepared to make use of steel and ceramic components that go into manufacturing and never into prototyping: that’s the ambition utilizing our personal patented NanoParticle Jetting™ (NPJ) know-how.

In the meantime, Xjet is a 3D printer producer that’s addressing probably the most difficult phase in additive manufacturing, metals and ceramics. Top quality, prepared to make use of steel and ceramic components that goes into manufacturing and never into prototyping, that’s the ambition utilizing our personal patented NanoParticle Jetting™(NPJ) know-how.

Man Zimmerman

3DN: How does NPJ work? What are the advantages of utilizing it?

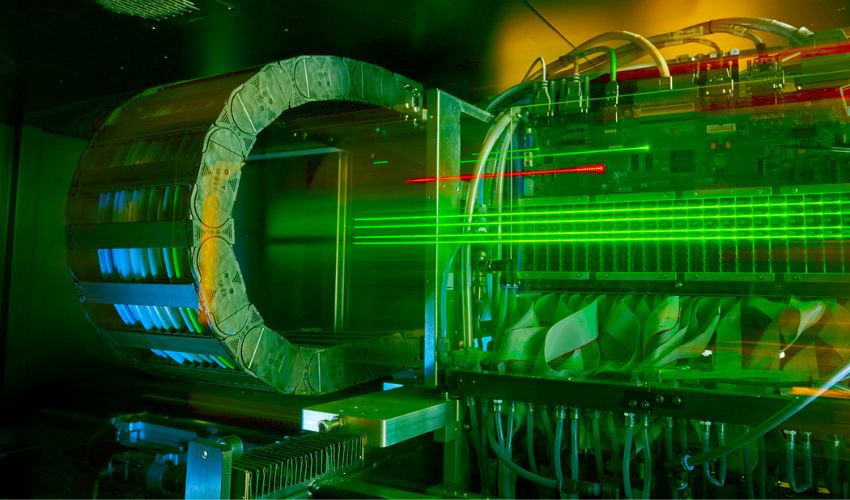

NPJ delivers clear, automated manufacturing of top quality components in steel and ceramics with out involving powders, guide labor, or submit processing . What permits this breakthrough is XJet’s distinctive additive manufacturing course of based mostly on nano-particles direct materials jetting, which print high-resolution components utilizing the hardest supplies in scale. On this course of, the assist supplies and the principle supplies are each inks, not powders, a revolutionary method in AM.

Let’s dive somewhat deeper into the printing process. We name it: Print-Wash-Sinter. The fundamental precept is utilizing procurable materials based mostly on nanoparticles. With this, we’re capable of concurrently print the fabric and the assist, which is a really onerous however soluble materials. As soon as we full the construct, the assist is washed away in water through an automated course of. The ultimate sintering part is completed in a normal trade furnace, however in a considerably decrease temperature than powder based mostly options. This permits the very best complexity, accuracy and a stage floor. It additionally removes design-related constraints. The know-how and the usage of skinny nanoparticle layers and soluble assist allow the creation of complicated, correct geometries, together with inside parts. This additionally permits for brand new design capabilities in a means that was thought of not possible up till now.

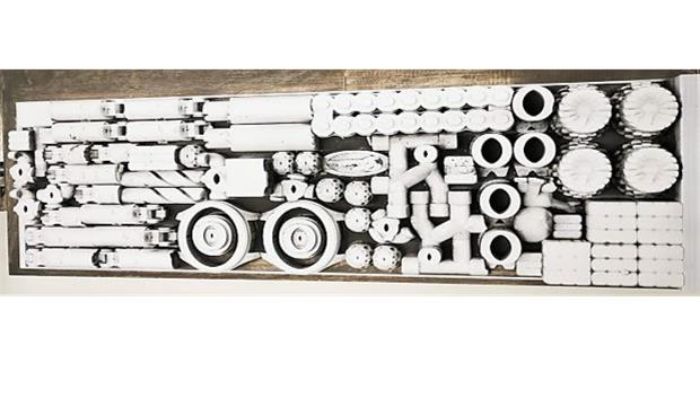

Xjet is able to making a variety of wonderful options

The result’s high-quality, extremely correct components straight off the method. The printed components don’t require any further processing or machining. Similar to the XJet slogan, all it is advisable to do is print, wash, and sinter.

One other benefit introduced by nanoparticles has to do with the power to print remarkably skinny layers. The density stage is considerably larger in comparison with different additive applied sciences, reaching highest ranges of fabric purity, density and floor smoothness. This considerably improves the components’ efficiency and reduces the sintering impact.

As you might know, the sintering course of turns the particles into the precise materials, which regularly ends in vital shrinkage. With XJet’s know-how, the method is completed at a temperature decrease than 200C, which saves time, boosts density, and reduces isotropic and total shrinkage. Shrinkage stays the identical alongside the x, y and z axes, leading to no distortions within the remaining half. This proprietary and groundbreaking know-how is packed in a excessive throughput manufacturing system. It’s a digital, automated course of as a substitute of a guide, unsafe, polluting course of that ends in lower-quality components.

3DN: What are the functions for Xjet’s options?

Along with our market main clients we’re focusing on particular verticals and functions in all three trade domains: Industrial, Medical, and Shopper items.

In terms of ceramics, largely Alumina and Zirconia, which provide very excessive resistance to warmth, corrosion and electrical isolation, the liberty of design we convey to this market opens up alternatives in industrial functions (e.g. semiconductors manufacturing tools components, warmth exchangers and electrical energy connectors, wave-guard antennas and electrical board components).

Xjet had been current at Formnext 2022

Dental implants and crowns are one other apparent vertical that we’re moving into which is likely one of the rising medical markets at this time. In shopper items we give attention to excessive worth wearables like high-end earbuds (which is an intriguing utility, because the printed components are very small, nonconductive, and customised to supply high acoustic qualities), and luxurious watches.

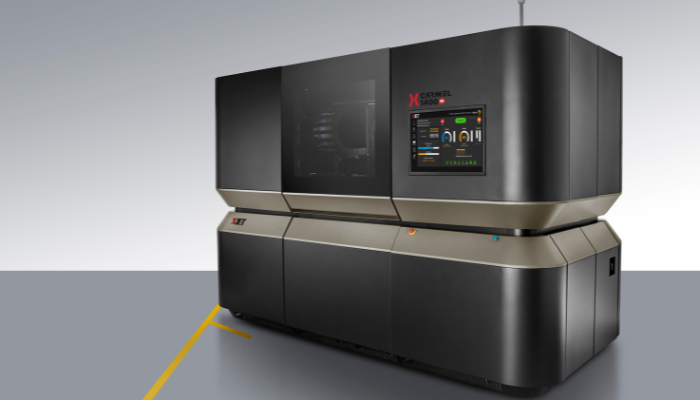

We even make a number of ceramic components in our excessive efficiency Carmel1400 system, so principally we print our personal components with our personal machines. Steel is a more moderen know-how coming into the market changing conventional MIM (Steel Injection Molding) for brief runs and excessive selection components like surgical units, hydraulic methods components and lots of extra.

We assist a spectrum of distinctive functions that require a excessive amount of components, changing a number of conventional applied sciences. The record consists of MIM (steel injection Molding), CNC, and funding casting, a central know-how with small components that struggles every time half manufacturing is underneath 20,000, making our know-how a extra economical selection.

3DN: Why did Xjet resolve to launch a steel answer?

After we established the ceramics know-how amongst market leaders and ceramic technical leaders, we finalized the event of the steel a part of the portfolio with two main stainless-steel supplies. Steel is a a lot bigger and diversified market. Growing the steel answer was tougher, however we’ve reached unprecedented efficiency ranges, even higher than ceramics. In early 2022, we launched it to the market after going by means of a protracted analysis course of.

It’s now out there, and we showcased it at Formnext 2022 with testimonials from the know-how’s main beta customers. Guests discovered how this steel answer competes with a number of powder-based applied sciences, providing clear benefits as an automatic, clear steel course of to be used in quite a lot of sectors.

Xjet’s steel answer

The know-how provides a number of advantages. First, we had been capable of develop soluble assist supplies that may work with the steel, an enormous benefit for a lot of customers. One other is the high-quality floor stage of the half, which is evident proper out of the machine with out demanding any further processes. The third profit is producing extremely complicated components with accuracy, an enormous benefit for a lot of functions.

Simply as an example this, we will print the wristband of a luxurious watch from stainless-steel as an entire. It’d want somewhat little bit of sharpening, however that’s it. We’re capable of print so precisely that we will print the wristband bearings contained in the half, no must assemble it. NJP offers customers the power to print extraordinarily correct, high-performance components in steel which can be ready-to-use because of the distinctive functionality of jet versus powder. We give attention to customers who wish to create high-performance, correct components in numerous consumer-facing verticals.

3DN: One other side you’re pleased with is the sustainability of your course of. How precisely is it environmentally pleasant?

To begin with, it’s secure. The supplies are secure, they arrive in closed bottles, and there are not any poisonous particles or free powder . It’s a secure course of for individuals who function it, which isn’t the case for a lot of AM and conventional processes. Moreover, it makes use of precisely the quantity of fabric wanted for the half. It doesn’t waste something in a very additive constructing course of.

Our assist materials is soluble in water and could be safely drained. It incorporates some minerals, however is so secure it may cross as consuming water in some locations. That is safer for people but in addition the atmosphere, because it virtually eliminates waste disposal points.

Final however not least, our sintering can be extra eco-friendly in comparison with many different processes. It’s sometimes probably the most energy-consuming a part of the method, however as a result of we conduct it at comparatively low temperatures for a decrease interval, we save numerous vitality. These key components make NJP some of the environmentally pleasant processes in steel and ceramics.

3DN: Any final phrases for our readers?

To summarize, NPJ know-how provides three main benefits. Nanoparticles in ink make it safer and extra correct, reaching larger density. The second profit is rooted within the constructing course of, printing the thinnest layers to realize unbeatable limitless complexities and true Design for Performance. And the third is the inexperienced component. Our components could be cleaned in water, leaving no residue.

The method itself consists of solely three steps: print, wash, and sinter. Transferring ahead, we imagine the know-how will turn out to be a significant half within the digital transformation of ceramic and steel, industrial, high-quality, complicated components manufacturing. You possibly can be taught extra about XJet on our web site HERE or take a look at the video beneath to know how our know-how works.

What do you consider Xjet? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly Publication right here, the newest 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*All Picture Credit: Xjet