Shenzhen primarily based expertise firm Elegoo was based in 2015, and has since constructed up a large 3D printing portfolio. On this article, we evaluation the Elegoo Saturn 2, a Masked Stereolithography (MSLA) printer with a 8K 10-inch mono LCD display.

The primary Elegoo printer to supply a ten” 8K display, the Saturn 2 was launched in Might of final yr, marking a brand new addition to the corporate’s rising line of desktop 3D printers, which incorporates the Mars and Neptune methods.

Key options and technical specs

An MSLA printer with a full metallic chassis, the Elegoo Saturn 2 can produce increased high quality components than different printers in the marketplace as a result of accuracy of its Mono LCD display.

Possessing a decision of 7680×4320 pixels and an XY decision of 28.5 microns, the Saturn 2’s HD display permits the manufacturing of extremely correct and detailed 3D components. Certainly, the Saturn 2’s display is 51.5% greater than the Mars collection’ 6.6-inch display, marking a major improve on the general high quality achievable from different Elegoo printers. Furthermore, the printer boasts an XY accuracy of 51μm, and a Z-axis accuracy of 0.00125mm, additional testifying to its print high quality.

The Saturn 2 additionally gives vital construct capability upgrades over its predecessors, incorporating a construct plate that’s 43% bigger than that of the unique Saturn mannequin. Coming in at 305mm x 273mm x 567mm and weighing 10.9kg, the machine has a considerable construct quantity of 219mm x 123mm x 250mm. This vital quantity permits customers to execute bigger builds, or print a number of smaller fashions in a single batch. Moreover, with print speeds of 30-70mm/h and remedy occasions of solely 1-3s per layer, the Saturn 2 gives vital time saving and effectivity for its customers.

With costs beginning at simply $600 USD, this printer is a very reasonably priced possibility inside the 3D printer market, enabling prime quality printing on a finances. Thus, the Saturn 2 is right for these searching for an entry degree DLP printer, and is especially suited to hobbyists and makers trying to produce small scale prototypes and fashions.

While Elegoo has launched their very own 8K resins that are marketed as being particularly efficient when used along side the Saturn 2, the printer can also be appropriate with third celebration resins. This provides the person better freedom in relation to their prints, while providing additional potential for price slicing.

Unboxing the Saturn 2

When delivery a 3D printer from China to Europe, as was the case right here, the packaging of the product is especially vital. Within the case of the Saturn 2, and its extremely delicate and delicate LCD devices, that is much more vital. Due to this fact, it was relieving to seek out that our Saturn 2 was extraordinarily properly protected, with the printer contained in a protecting foam layer inside the cardboard delivery field. A number of massive foam blocks had been additionally added to guard the Z-axis, guaranteeing no Z-axis motion throughout delivery, a really considerate addition from Elegoo. The printer additionally got here wrapped in plastic, minimizing any scratches or floor marks which might happen in the course of the packing and unpacking course of.

Unboxing the Saturn 2. Photographs by way of 3D Printing Business.

The Elegoo Saturn 2 equipment got here with a person handbook and all the mandatory equipment required for a desktop resin printer, with an air air purifier, protecting masks, plastic print scraper, metallic print scraper, USB key, energy cable & brick, gloves, aspect slicing pliers, and resin filters all included. Additional nuts and bolts, in addition to the instruments wanted to put in and manipulate them, had been additionally included with the printer.

First impressions

The printer sports activities a glossy design, and is made up of black and grey plastic and clear purple acrylic. With a workspace of 6.7 liter cuboid, the Saturn 2’s capability is respectable for a resin printer of this measurement. This workspace is encased by a purple plexiglass protecting shroud that may be lifted off vertically to entry the resin tank and completed components.

As a completely enclosed machine, this protecting cowl is important for conserving the printing house freed from UV gentle. If uncovered to UV gentle, the resin will polymerize which might trigger the print to fail, making the printing enclosure a very vital a part of the machine. The Saturn 2’s enclosure additionally prevents dangerous resin fumes from escaping the workspace. A small activated carbon air filter can also be included which, when plugged contained in the machine, additional aids in stopping the leaking of dangerous fumes.

The Saturn 2 is fitted with an anodized aluminum resin vat with an FEP movie fastened beneath. This reservoir can maintain as much as 500ml of resin to the max line, and is secured to the machine by 2 M3 bolts on both aspect of the construct space, with some pegs included to assist in lining up the vat to the display. Under the resin vat is a glass plate which sits above the LCD display.

To make sure all gentle is parallel when coming into the resin, the display makes use of a Fresnel Collimating Gentle Supply, an industry-first patented expertise developed by the ELEGOO R&D group. The Fresnel lens makes use of an optical lens method which limits the sunshine angle below 5 levels, overcoming the large-angle downside of typical COB gentle sources and the sunshine spot downside of matrix gentle sources. Thus, this expertise ensures a excessive degree of accuracy and reliability, while facilitating the manufacturing of sharper and extra practical printed fashions.

The Saturn 2’s print platform development floor has been sandblasted to realize higher resin adhesion, and is linked to the Z-axis chassis by way of a big thumb bolt on the highest of the construct plate. This mechanism gives sufficient energy and safety to maintain the construct plate degree and motionless throughout printing. Setting the Z offset is a handbook course of, with two bolts positioned on the print platforms metallic bracket needing to be unscrewed whereas the printer houses the mattress. When the mattress is at its minimal degree these bolts should then be tightened to make sure an correct first layer and minimal failed prints.

The printer has a 3.9-inch full-color touchscreen multilingual person interface that could be very intuitive and straightforward to make use of, and is conveniently positioned on the backside entrance of the printer. The person interface permits the person to manually degree the mattress, expose the vat to UV gentle, Z offset, cease print, and clear the resin vat. A USB port can also be positioned on the rear of the printer, enabling information to be loaded on the printer from a USB stick.

The Saturn 2’s 3.9 inch display and USB port location on the rear of the printer. Picture by way of 3D Printing Business.

As with most printers we evaluation, our first impression of the machine’s printing skill comes from the included check file. Delivered with this printer by way of a USB stick, the check file we printed was a small fortress chess piece, providing an early alternative to evaluate the Saturn 2’s element and accuracy for small fashions. Typically, these components are optimized for the printer, and shouldn’t pose any issues for a 3D printer value its salt. On this case, the check piece printed flawlessly, highlighting some intelligent inside geometries solely attainable by additive manufacturing. Our engineers had been impressed with the element and end right here, definitely marking a very good first impression for the Saturn 2.

Slicer

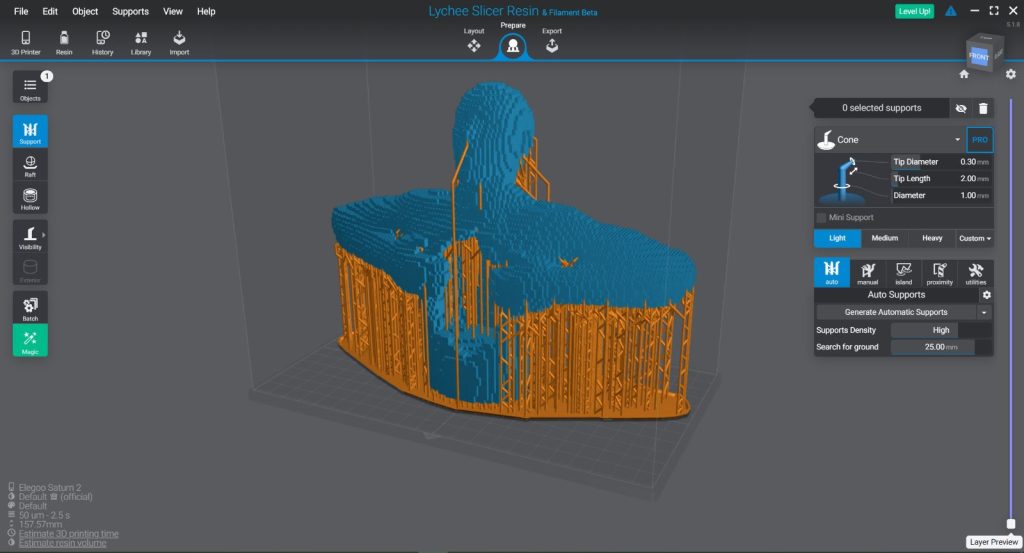

Elegoo doesn’t provide its personal slicing software program, as an alternative recommending prospects use both Lychee or Chitubox slicers. Each of those are good choices, and we used a small check (extra on this later) to gauge which might be greatest for our evaluation, with Lychee popping out on prime.

Lychee is appropriate for novices, being easy-to-use with a transparent interface, but in addition incorporates extra superior choices and options for knowledgeable customers. Notably, Lychee gives a “Magic” button which might routinely regulate plenty of settings equivalent to orientation, helps, optimize helps, bracing helps, raft, and help presets (gentle, medium, heavy).

Preset profiles can be found for the Saturn 2 inside the slicer, while settings may also be manually tweaked to satisfy person necessities and preferences. As an illustration, the person can edit sure materials settings together with decision, publicity time, and the variety of backside layers. As soon as slicing has accomplished, the print file might be exported onto a USB drive, which is then inserted into the Saturn 2 to begin the print.

Finally the entire slicing expertise was constructive, with the software program being simple to make use of and possessing good ergonomics. Nevertheless, Elegoo’s providing might definitely be improved with its personal devoted slicer, particularly if the corporate needs to take its printers to the following degree and compete with the opposite high-end resin machines in the marketplace. Certainly, devoted slicing software program, and the addition of Wi-Fi connectivity, would vastly streamline the printing course of, and permit options equivalent to wi-fi printing and print monitoring.

Benchmarking the Elegoo Saturn 2

We started our benchmarking with the 3D Benchy. Though predominantly used for testing layer adhesion and overhangs on FDM machines, these identical ideas might be utilized with resin primarily based methods, making this basic check very best for benchmarking the Saturn 2. As an illustration, overhangs can nonetheless incessantly trigger points with resin printers, the additive course of working in a lot the identical means as with FDM. Furthermore, by permitting analysis of overhangs, bridges, holes, and inside detailing in a single check, the 3D Benchy is right for performing a fast all-round evaluation on print accuracy.

This can be a check that any respectable printer ought to go, with a failed print both indicating the necessity for effective tuning, or a extra major problem.

3D Bency Boats printed utilizing the Saturn 2. Photographs by way of 3D Printing Business

As you possibly can see, the standard of this print was actually spectacular, with this being among the best benchy’s we’ve ever had. The standard of the LCD display definitely shines by, with no layer delamination or mattress adhesion points current right here. The print layers will not be seen, and the form of the hull is excellent, making this an excellent high quality print.

Throughout our check we seen some discrepancies within the Z-axis when printing immediately on the mattress. Due to this fact, we determined to print a separate model utilizing helps with the identical orientation, in the end giving us the outcomes we had been anticipating.

Subsequent, we subjected the Saturn 2 to a repeatability check, whereby we assessed the printer’s skill to provide a number of components with the identical dimensions. Every half’s dimensions had been then in comparison with the unique 3D mannequin to establish any deviation in measurement. Finally, the Saturn 2 produced blended outcomes for this check, with some key points being highlighted.

On the one hand, the X & Y axes possessed a mixed common deviation of 0.0572mm, simply over the anticipated determine of 0.05mm – the common deviation for a resin printer of this high quality. Nevertheless, when the outcomes for the Z-axis had been included, the general common deviation rose to a regarding 0.174mm, indicating a major subject with the Z-axis. A regular deviation of 0.0941mm, which lowered to 0.0736mm when excluding the Z-axis, additional pointed in the direction of a difficulty right here.

Upon deeper investigation, we discovered that, since we had been printing the components immediately onto the print mattress with out helps or a raft, the primary few print layers had been burnt in and warped, thus inflicting imperfect and inconsistent outcomes. It was crucial to make use of excessive temperature settings on these first few layers with a view to enhance adhesion, sacrificing print accuracy as a consequence.

The distinction between measurement and reference. Figures by way of 3D Printing Business.

Finally, these points will impression the person relying on their functions and the particular use of the machine. When used to provide components which don’t require stringent accuracy, the person is unlikely to note the inexact nature of the components. Nevertheless, if utilizing the machine for exact CAD fashions, these Z-axis inaccuracies will seemingly trigger points, and require focused tuning to resolve.

Apart from these accuracy points, the general high quality of the print was superb, once more testifying to the advantages of the Saturn 2’s HD display. The half’s all possessed clean surfaces, and there was no layer delamination. As soon as cleaned inside an ultrasonic cleaner with isopropyl alcohol and cured with UV gentle, the components got here out completely. Nevertheless, it’s value noting that, if left within the machine for too lengthy with out curing, the resin does tend to start texturing on the partitions.

Repeatability check items. Photographs by way of 3D Printing Business.

Subsequent, we carried out a tower check to find out whether or not the printer is able to producing tall and skinny components, with the specified half dimension being 20mm x 20mm x 250mm. This may be a difficulty for 3D printers, with this check usually inflicting delamination on resin printers. But, the Saturn 2 carried out significantly properly right here.

The half produced by the Saturn 2 had dimensions of 19.84 x 19.85 x 248mm, extraordinarily near the specified dimensions and successful given that almost all resin printers are 2mm offset from their listed construct quantity.

We adopted the tower check with a width check, which appears to be like to check the width limits of the printer’s construct space. The slicer accepts fashions as much as the printer’s construct space limits of 219mm x 123mm, with our printout measuring 218.5mm x 122.5mm. Nevertheless, we encountered some vital issues throughout this check, in the end failing to provide a profitable print.

The principle subject we encountered associated to adhesion on both excessive of the X-axis on the mattress. We firstly carried out a number of completely different leveling assessments on the print mattress which didn’t resolve the problem. We then found that the mattress we initially acquired was not degree, having a slight convex curve alongside the X-axis. This created an uneven floor and triggered one aspect of the X-axis to carry up when the opposite was pressed down, explaining the adhesion points.

Having put in a substitute print mattress with out deviations we noticed a slight enchancment, nonetheless had been nonetheless unable to provide an ideal width check. This was disappointing, and could be a major subject for customers hoping to print massive parts taking on a lot of the print mattress. Nevertheless, if used to print smaller components equivalent to fashions or small prototypes, this print mattress shouldn’t trigger any actual issues. Furthermore, while print mattress points might definitely turn into apparent straight out of the field, tuning the slicer profiles can produce improved outcomes for bigger prints. Finally, nonetheless, this failed check was disappointing and positively signifies an space of enchancment for Elegoo to work on for future printers.

Varied failed width assessments. Photographs by way of 3D Printing Business.

To check the Saturn 2’s overhang printing capabilities, we created a six wall print with overhanging angles rising from 40° to 65°. As soon as once more, the Saturn 2 didn’t carry out in addition to we had hoped, with not one of the overhangs being utterly straight, all having a slight curve in the direction of the tip which will get progressively worse because the overhang angle will increase.

While the widespread overhang restrict for many resin printers is 55°, the Saturn 2 appears to have a restrict of simply 40°. That is once more disappointing, and will definitely have actual world implications for customers. Thus, that is one other key space for enchancment value contemplating on the a part of Elegoo.

Overhand check items. Photographs by way of 3D Printing Business.

Lastly, we assessed the printer’s skill to provide small and exact components, on this case a useful nut and bolt mannequin with a size of about 28mm. Right here, the Saturn 2 excelled, as soon as once more demonstrating the advantages provided by its 8K 10-inch mono LCD display. The printed components possessed good element, had no defects on the thread, and could possibly be efficiently screwed collectively as supposed.

Small and exact components check. Photographs by way of 3D Printing Business.

Potential Saturn 2 functions

Throughout testing, we additionally printed plenty of fashions and prototypes in an effort to evaluate the potential actual world functions of the Saturn 2.

Firstly, as talked about earlier than, we carried out a check print to find out which slicer to make use of for our testing. Right here we selected to print two similar small Land Rover fashions, not a lot bigger than a 10p coin, utilizing each Lychee and Chitubox slicers. Finally each prints got here out very well, with the Lychee’s “magic” instrument edging it out on prime forward of Chitubox. This print definitely signifies the Saturn 2’s skill to provide good high quality and detailed small fashions.

Land Rover fashions. Photographs by way of 3D Printing Business.

The Saturn 2 additionally demonstrated a capability to provide bigger and sophisticated detailed prints, having succeeded in printing our Huge Ben mannequin. This print got here out completely, with our engineers being significantly impressed by the detailed arches and determination of the clock face, with minimal put up processing required after printing. As soon as once more, the Saturn 2 has confirmed itself as a worthy instrument for these trying to make excessive decision and detailed fashions.

With the intention to conduct a extra correct measure of the real-world printing course of, we carried out a more difficult print of a number of detailed military automobile miniatures. Furthermore, printing a number of fashions concurrently allowed us to check the print beds adhesion points in a real-world context. These prints got here out higher than anticipated and, regardless of one failed mannequin in the course of the cluster, might be seen as successful for the Saturn 2. The printer is definitely appropriate for the manufacturing of small fashions and miniatures, although customers must be cautious of potential points cropping up as a result of beforehand talked about print mattress points.

3D Printed military automobile miniatures. Photographs by way of 3D Printing Business.

Subsequent, we needed to check the printer’s skill to provide prototype components, for extra skilled functions. To realize this we regarded to print the entrance plate of a video games distant, scanning the half and printing it with a transparent inexperienced materials. This print got here out completely with no layer adhesion points, definitely testifying to the Saturn 2’s prototyping capabilities.

Video games controller housing. Photographs by way of 3D Printing Business.

Resin printers are sometimes used to print lattice buildings for functions equivalent to sports activities gear. To check this software, we tasked the Saturn 2 with printing a fancy lattice construction. The printer rose to the event, producing a high quality half with no defects and faultless post-processing, impressing our engineering group.

3D printed lattice construction. Photographs by way of 3D Printing Business.

Lastly, we tasked the Saturn 2 with producing a 3.5mm audio jack injection mould, testing the machine’s skill to print a prototype making instrument which requires good floor high quality and element. This was one more constructive end result. There have been no faults, and the components inside floor was significantly clean.

3D printed audio jack injection mould. Photographs by way of 3D Printing {industry}.

Our remaining verdict

There’s nonetheless room for enchancment for the Saturn 2, and prospects ought to pay attention to the problems we encountered earlier than making a remaining resolution. The printer’s lack of ability to print a full width-test was unlucky, and will trigger issues for these trying to produce bigger components, while the repeatability failures are additionally value contemplating. Moreover, while the Lychee slicer carried out properly all through our testing, we consider the addition of a devoted Elegoo slicer would positively enhance performance and reliability.

Nevertheless, we nonetheless view the Saturn 2 as a worthy addition to Elegoo’s resin printer portfolio. Simple to make use of and providing an especially excessive degree of element and print accuracy, this machine is an efficient possibility for mannequin makers of all ranges. Furthermore, with a aggressive beginning value of simply $600, we consider that this machine gives nice worth for these searching for prime quality printing on a finances. This printer has a excessive potential, and we’re assured that, with some tweaking and bug fixes, the Saturn 2 might turn into one of many prime decisions for novices trying to get into resin 3D printing.

Subscribe to the 3D Printing Business publication to make sure you sustain with the most recent 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing {industry}? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture reveals the Elegoo Saturn 2. Picture by way of 3D Printing Business.