Flexible, wearable strain sensors monitor tiny vibrations in the skin of humans. This is possible thanks to new fabrication techniques that use composite materials. A high-quality strain sensor must have high sensitivity and a large working range. However, it is difficult to achieve both these characteristics with the same sensor because of limitations in conductivity and structure.

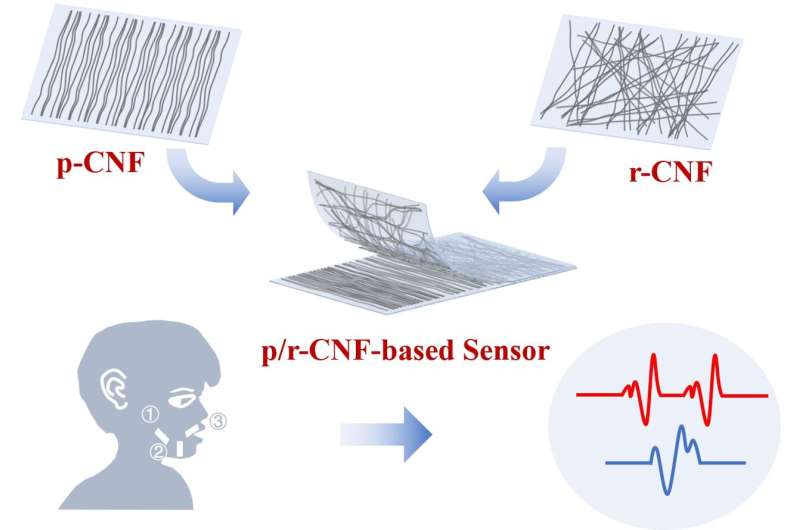

Researchers from Tsinghua University have created a flexible strain sensor using a membrane that is made of stacking parallel and randomly aligned CNF nanofibers (CNF). This design achieves high sensitivity and wide range of strain detection.

The study was published by Nano Research.

Flexible strain sensors are useful in activity and health monitoring, smart textiles, and human-machine interaction. A flexible strain sensor was developed by the Tsinghua University research group for a lip language recognition system. This can be used to help people with damaged vocal chords communicate daily.

Peng Bi, first author at Tsinghua University said that “The lip language recognition system can quickly and easily translate sentences for people suffering from damaged vocal cords.” This greatly reduces communication barriers.”

This flexible sensor must be able to detect subtle movements and collect large amounts of information. Bi said that the only way to satisfy this requirement is to create a flexible strain sensing device with both high sensitivity as well as a broad range of strain detection.

Flexible sensors, unlike conventional sensors made out of bulky, rigid metal, can conform to the human skin and move without causing discomfort. These sensors are made from elastic polymers that have been combined with conductive materials like graphene, carbon Nanotubes, metal particles, metal nanowires, liquid metals and metal nanoparticles. This allows them to be integrated into clothing, or stick directly to skin.

Up to now, most reported wearable strain sensors showed either large workable strain range or high sensitivity—but not both. A strain sensor that has a large range of strain detection may be flexible or stretchable by more than 400%, depending on the material. Low gauge factor values are an indication of sensor sensitivity. They can detect tiny vibrations under the skin but have a wider range.

Both of these advantages seemed to be mutually exclusive. In order to achieve high sensing, the conductivity within the microstructure sensor layer must change dramatically when a vibration occurs. To achieve wide sensing range, however, the sensing layers should be constantly conductive even under high tensile strain. The sensors that are composed of only one conductive medium seemed to have a limited sensitivity and a narrow range of detection for strain.

Bi and the Tsinghua University group devised an approach to simultaneously realize both desired features.

A membrane with carbon nanofibers aligned parallelly (p-CNF), has a lower strain detection limit and high sensitiveness, while a CNF membrane that is randomly aligned (r-CNF), has a greater strain detection range. The researchers created a flexible strain sensor by stacking parallel carbon nanofiber membranes.

Bi said, “Remarkably the obtained p/r CNF based strain sensor showed an extremely low strain detection limit as low as 0.005% and a ultra-high gauge value of up 1272 strains under 0.5%.” “Its maximum strain detection limit is 100 percent, which meets the requirements for most human movements.”

The sensor can accurately detect large movements like joint bending as well as minor motions like facial expression, eye rotation and pulse.

They created an intelligent system to recognize lip-languages using p/r CNF strain sensors, Arduino, and a loudspeaker as proof of concept. The system “reads lips”, can correctly track phonetic symbols through lip movements and executes the corresponding instructions such as audio or output lights.

Bi stated that the recognition system could help people with language impairments, and demonstrates the potential of the strain sensor in medical management and health assistance.

The current lip-language recognition system cannot handle certain communication scenarios or locations.

Bi stated that the Lip-language Recognition System will be used in a variety of applications and the wearability and comfort of the device will be improved. “We hope such a wearable device could become a second-mouth for people with vocal chord damage and minimize the effects of this injury on someone’s day to day life.

Other high-performance sensors may also benefit from the dual-alignment design of the p/r CNF strain sensor.

Additional information:

Peng Bi et. al. Ultra-sensitive strain sensor that is universally applicable and can be used by carbon nanofibers that have dual alignment to allow for human-machine interfaces. Nano Research (2022). DOI: 10.1007/s12274-022-5162-0

Provided by

Tsinghua University Press

Citation:

Carbon nanofibers enable flexible strain sensors that can read lips (2022, 29 November)

Retrieved 29 Nov 2022

from https://phys.org/news/2022-11-flexible-strain-sensor-enabled-carbon.html

This document is subject copyright. Except for fair dealings for private study or research purposes, there is no

Without permission, part of the content may be reproduced. The information is provided only for informational purposes.