In anticipation of the upcoming drupa present, there may be often a “pre-drupa” media occasion. This has been the place for a sampling of the exhibitors to put out what they see as their future route and even pre-announce a few of their newest applied sciences.

Since 1951, drupa, occurring each 3–5 years on the Messe Düsseldorf in Düsseldorf, Germany, has at all times been thought of the bellwether of the graphic arts business’s growth and future. This 12 months is exclusive; for the reason that pandemic broke the common rhythm, there may be a whole lot of catching as much as do. This makes it particularly distinctive as a result of the market necessities and expertise adjustments throughout this era have elevated their competitors past the norm.

In anticipation of the drupa occasion, there may be often a “pre-drupa” media occasion. This has been the place for a sampling of the exhibitors to put out what they see as their future route and even pre-announce a few of their newest applied sciences. This 12 months, the occasion was held in March, two months earlier than the official opening of drupa 2024. Whereas there has at all times been an curiosity in assigning an figuring out tagline that represents the spotlight for every of the drupa occasions, this 12 months we appear to have not less than three. These are: digitalization, clever course of automation, and sustainability.

You possibly can anticipate to see some if not all of those three themes within the applied sciences and choices at drupa. The next are only a small sampling of what is going to be proven.

Bobst

Along with new press and changing options, Bobst Join is the cornerstone that brings every little thing collectively for the corrugated board, versatile packaging, folding carton, and label manufacturing industries. Bobst Join is a cloud-based digital platform designed to make sure an environment friendly knowledge movement between bodily and digital world with an automatic and digitalized manufacturing movement. In keeping with that, they introduced the launch of two main options for Bobst Join. The primary is Job Recipe, which permits seamless integration of Bobst machines in manufacturing and design workflows, bidirectional job and recipe knowledge synchronization for quick setup and enhance productiveness. The second function is Vitality Monitoring, enabling prospects to measure their vitality consumption and price in actual time driving effectivity enchancment and price financial savings within the corrugated market to answer the rising demand from e-commerce to stylish sort of packaging to be produced in a extra automated and sustainable method.

Canon

The ProStream 2000 collection is the most recent addition to the continuous-feed inkjet portfolio. There are two fashions, the ProStream 2080 and the ProStream 2133, providing two pace variations, 80 m/min. and 133 m/min., and a most net width of 558mm. The Professional Stream 2000 collection is predicated on 1200 dpi fields for electrical drop-on-demand heads, and makes use of the Canon Shade Grip sensible paper conditioning liquid. It requires 29% decrease energy provide than its predecessor and 6% decrease exhaust volumes and warmth emissions which interprets into a complete of lower than 10% much less vitality consumption than the professional stream 1000. The flagship of ProStream 3000 collection will get new fashions with the ProStream 3160, working at 160 m/min. It should use the identical ink that can launch with the ProStream 2000. Of their EP line, they’re additionally extending the ColorStream 8000 with the ColorStream 8200, providing 200 m/min. productiveness.

Extensive-format introductions will embody fashions from the Picture Professional, the Plot Wave, Shade Wave, Colorado, and Arizona collection. They are going to be introducing the Arizona 2300 collection with Flex Circulation expertise. The brand new Flex Circulation vacuum desk is an enhanced media dealing with system that helps operators to raised deal with difficult substrates corresponding to heavy media, delicate media, or odd-shaped media. Arizona additionally will get Flex Circulation expertise which could have its European debut at drupa. They can even showcase corrugated board manufacturing with the Arizona 2380 XT.

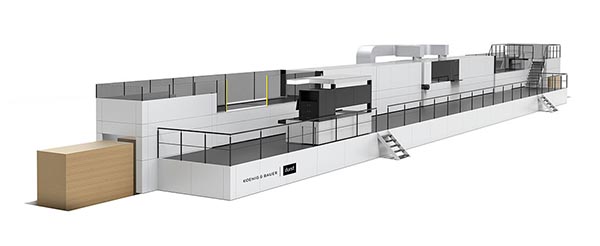

Canon additionally introduced which might be totally engaged in bringing a line of packaging presses to market. At drupa, they may enter the corrugated market with a devoted product. They are going to showcase the idea of an industrial scale corrugated press, Under is the primary rendering of the product. It’s constructed on an structure that features a single move sheet fed transport with 4 to seven colours utilizing water-based inks. It boasts a productiveness degree of 8,000 sq. meters an hour and a print width of 1.7 meters vast. They’re aiming for installations of the primary corrugated press someday mid 2026.

Durst

They are going to be launching a brand new hybrid press which is a mixture of a twin servo cylinder-based flexo expertise from Omet and Durst RCI digital print engine. This can carry the operator simplicity, ease of use, minimal setup waste, and minimal setup occasions.

Durst introduced that their entrance and backend analytic AI options like Hawkeye at the moment are applied in each printer, and greater than a thousand prospects are operating with these software program options efficiently. Durst has made it a spotlight to associate with others to get to market sooner and enhance product benefits. Omet is a superb instance, however so is their partnership with Koenig & Bauer which has produced the VariJET 106, the CorruJET 170 and the Delta SPC 130.

Whereas there was a whole lot of dialogue about packaging on the media occasion, Durst emphasised that it’s in graphics, packaging, ceramics, and extra. At drupe, they are going to be exhibiting options for technical ceramics. It’s silicon carbide printed for the primary time. Purposes embody automotive, aerospace, and so forth.

Esko

Esko introduced the brand new Esko cloud platform. Over the previous couple of years, the expertise has drastically advanced. Cloud applied sciences and machine studying at the moment are totally mature, and that’s one thing that they will actually leverage to speed up innovation and to carry to their prospects. First, they’re connecting all their current merchandise. They wish to make sure that they’re preserving the funding of their prospects of their merchandise. So they’re taking all their desktop merchandise and connecting them to the cloud. They’re additionally including some new cloud-based options on prime of it. They’re taking collaboration and automation merchandise like Automation Engine and Net Middle, connecting them, sharing the information, sharing the consumer administration in order that they will prolong the scope of collaboration and automation. This isn’t solely software program product, but in addition {hardware} product like CDI and XPS are related to this platform in order that they will shut the loop to acquire full end-to-end automation.

Fujifilm

Because the FujiXerox relationship dissolved, Fujifilm has been operating and growing sooner. If their sales space at PRINTING United was any indication, and contemplating they’ve one of many bigger cubicles, that can maintain you busy. Their Revoria line of toner presses could be discovered not solely with their branding, but in addition with that of others. At drupe, they are going to be exhibiting their Revoria Press GC12500, the one B2 toner press available on the market for the primary time in Europe. They can even be exhibiting their FP790 aqueous based mostly versatile packaging press. They can even be exhibiting the Jet Press 1160CFG, their excessive pace steady feed inkjet printer for the primary time globally.

Heidelberg

At a really excessive degree, Heidelberg has a twin monitor technique. The one monitor is their core enterprise of printing, and that can stay to be printing, since that is what Heidelberg stands for. Nevertheless, they proceed to discover new and adjoining enterprise areas. The primary one is their charging expertise for electrical autos. That’s not a primary focus at present, however it’s an space can also be pushed by megatrends, which has a considerable market dimension, and matches effectively to their capabilities. They bolstered their ambition is to proceed to be a market shaper within the printing business. There’s a whole lot of change within the printing market, and the place there may be change, there are additionally alternatives. Two of these alternatives are the rising packaging phase and the rising digital printing phase. Each segments are extremely related for Heidelberg.

There are numerous drivers of competitiveness, most significantly the fee per sheet. Print retailers that concentrate on effectivity by enhancing their productiveness helps them to get price per printed sheet. From an tools perspective, actually the printing pace is most necessary, however it’s not all about pace. It’s additionally concerning the clever administration of print jobs and the complete manufacturing course of within the print store. So print jobs want an end-to-end integration of their processes. The second space is the workforce and we wish to assist print retailers to develop their workforce.

Digitalization is an absolute prerequisite for higher effectivity in industrial print manufacturing. So, they’re growing options that combine the workflows finish to finish to optimize uptime and manufacturing effectivity. Heidelberg truly has been a pioneer within the business on the subject of digitalization of their {hardware} with software program options.

HP

Productiveness isn’t solely pace. HP has been working for the final three years on reliability, greater machine availability, wider versatility, superior automation, and operational simplicity. We have now seen different producers deal with these areas, as a result of these are a number of the parts that have an effect on OEE. Marcus Weiss, common supervisor for EMEA for the HP industrial enterprise, highlighted their deal with “ease of use,” “as a result of in a world the place we have now much less labor, the place we might not have the experience degree, we want presses which might be simple to function.” For instance, HP launched PQ Maestro an computerized calibration instrument. That is a man-made intelligence high quality and calibration instrument initially for the 120K and as effectively within the 18K that’s utterly impartial from the operator of the press. It’s purely measuring the outcomes towards the goal.

To assist the expertise and their prospects, HP believes in totally automated workflows which might be pushed by enhanced AI. These workflows are overseen by the people, the place ultimately, the manufacturers, the suppliers, the resellers, all of the stakeholders available in the market are related with one another. They not too long ago introduced that they’re now working carefully along with Esko on options from the inventive software by means of the transport of the ultimate package deal or product with a totally automated and built-in provide chain of our their prospects.

HP additionally introduced that it’s getting nearer to a handover level from LEP to LEPX as seen within the V12. Shifting from a typical impression cylinder to inline permits the Indigo expertise to drive elevated pace and productiveness. Count on to see some new LEPX software choices at drupa.

Highcon

The Beam 3 is constructing on the expertise of current Beam collection allow the consumer to ship a 50% leap in productiveness with greater high quality. New {hardware} adjustments and algorithms scale back arrange time and predictability. They’ve additionally decoupled the crease writing from the die cutter with the Highcon Beam Author. Crease writing can occur as a parallel course of reasonably than as a serial course of, additional shortening arrange, and that releasing up manufacturing time to will increase capability by round 25% for a mean carton buyer. It additionally produces a 15% greater operating pace. They’ve launched new creasing drums within the DART system and people additional enhance the crease in high quality. To reduce the variety of touches and to scale back the dependence on expert personnel they’ve additionally partnered with Esko and Hybrid Software program along with growing their very own new software program instruments.

Additionally they introduced the Vulcan (growth title), the primary digital die-cutting answer for the 1.4 by 1.7m format of the corrugated business. Vulcan remains to be underneath growth, and is predicted to be an lively product of their portfolio at drupa 2028.

Konica Minolta

Konica Minolta shall be exhibiting finish to finish software options, together with a brand new guide answer with ending by Plockmatic. KM can even be exhibiting the Alpha Jet, from their associate firm MGI, and asserting their first consumer. They are going to be premiering a brand new minimize sheet B2 press the AccurioJet 60,000, a 6,000 sheets per hour B2+ UV inkjet press.

Landa

Landa shall be introducing the brand new Landa S11 and S11P fashions together with a brand new ink drying system that permits switch of dry ink from the blanket to the media, on the greater pace of 11,200 SPH. Not like majority of inkjet presses, the Landa expertise benefit is that it might run all kinds of media, together with paper, plastics, and so forth. The brand new Landa S11 and S11P could be custom-made with a alternative of 4 or seven colours, a steady printing functionality, and an non-compulsory inline coating unit. Current prospects with the IR drying have a chance to buy the 11K Module elevating productiveness to 11,200 SPH, and/or the PrintAI module.

In Closing

That is only a small sampling of what we will anticipate to see at drupa. Not simply because there shall be so many producers and answer suppliers, but in addition as a result of lots of them are holding again till the precise occasion.

So you’ll be able to anticipate numerous reside, persevering with, and follow-up protection!

Extra to Come…

It’s a brand new 12 months and the drupa 2024 mild is starting to blind us! Will probably be an thrilling occasion and lots of new merchandise and applied sciences shall be proven for the primary time. I wish to tackle your pursuits and issues in future articles because it pertains to the manufacturing of Print, Packaging, and Labels, and the way, if in any respect, it drives future workflows together with “Business 4.0.” You probably have any fascinating examples of hybrid and bespoke manufacturing, I’m very anxious to listen to about them. Please be at liberty to contact me at [email protected] with any questions, ideas, or examples of fascinating purposes.